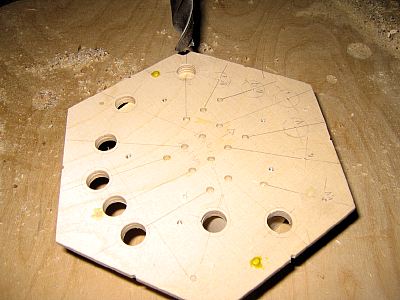

Making holes in thin wood was worrying, until I tried the modified drills made by Roy, the fabulous tool maker around the corner. In the raw bushing boards (3 mm plywood) they cut flawlessly, leaving polished holes with knife-sharp edges. I use 4 drills: two for air holes, one for the bushing board and one for the brass inserts that hold the hand strap screws.

I learned one thing: drill from one side only, right through – otherwise there may be an offset of a couple of tenths of a millimeter, if it is done from both sides. And even from one side, the edges are sharp and clean.

Roy Nilsson’s handiwork - emphasis on hand! His high-end

machinery is not involved here: he starts off with a new drill,

grinds the end flat, then shapes the cutting edges:

Like this. Watch fingers!

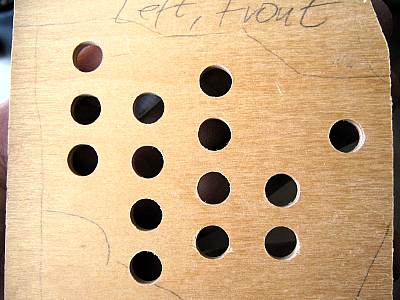

One bushing board drilled. “Cutting in butter” is the

appropriate expression.

Encouraged by the drilling of the bushing boards, I continue

with the air holes.

Next Previous