Armed with knowledge that the sides should be 86,8 mm, the next task is clear (though not necessarily easy):

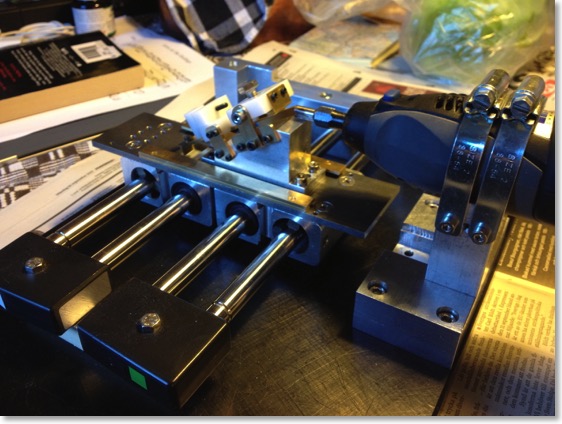

This monster can route the Gammage joint, fine-tune the length of the sides and make anything hex-shaped. The whole shebang is based on discarded parts from a Gambro Acute Dialysis machine: four SKF linear ball bearings that run on 12 mm polished steel rods. Smooth...

This is the set-up for the joint:

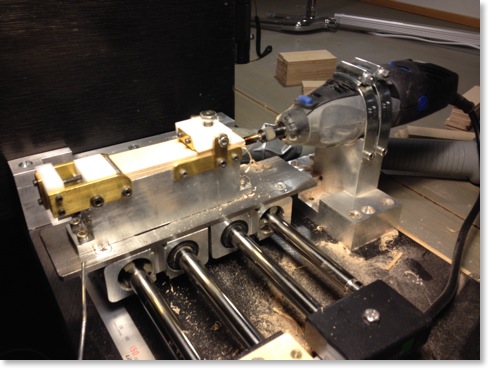

When the joints are done, the set-up is changed:

It allows very little to be shaved off the ends, the process being: take off enough on one side and verify that is is getting close to ≈89 mm. Do six sides and see if they can go into the mould. No? Take off a little more, until they fit.

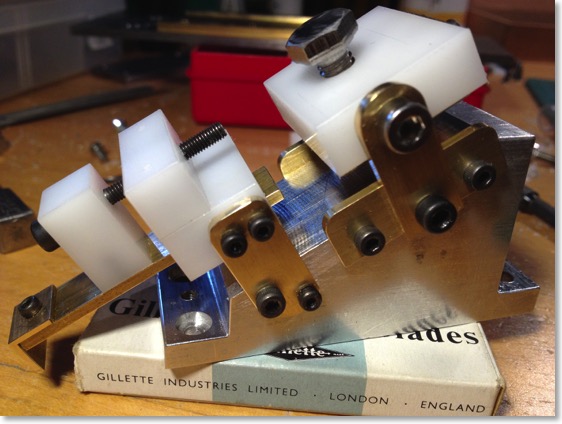

The bellows frames and the end box frames now takes different roads: the end box sides get a little track routed that will allow the bottom of end box to fit snuggly up into the frame. The bellows frames don’t get that - they get something else: special treatment in this tool:

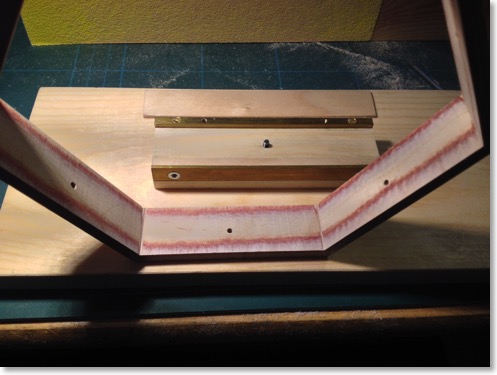

The jig facilitates the making of the inside taper of the bellows frames:

Each side of the frame is fixed (with threaded hole for 3mm screw) in the jig and then “filed” (60 grit paper on a thick stick of wood) until the file “idles” on the rollers (electricians’ tube on aluminum rod). Another benefit of using aircraft ply: you can see what happens as you file away.

Next Previous