The laser cut frames looks great, but needs adjustments: the sides should have an angle in order to fit tightly in the dovetail track. And “tightly” means that the final adjustment is done on the individual frames, i.e., a frame is made to fit a specific track and only that.

To start the angles, I have made two jigs:

A jig for left side, a jig for right.

The frame rests (inside the jig) on a strip of brass, angled 5°, so the visible part will be horizontal. Screws at the end can adjust the position of the frame, hence the height - to ensure that I don’t take of too much material. When the file starts to run freely on the rollers, it’s done.

The rest = fitting the frames to the reed pan tracks, was done by hand. Took a long time...

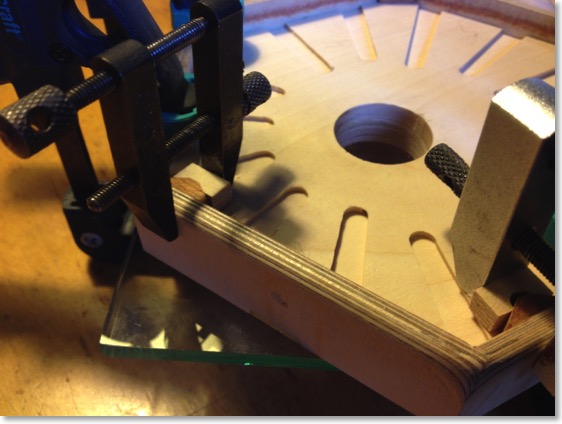

Oh, yes, by the way: before all this was done, the supports for the reed pans were glued in place:

The reed pan is placed upside (“wallside”) down on a thick glass plate and the bellows frame is placed over it - after double/triple-checking that the top corner of the bellows frame was aligned with the top corner on the pan. Glue, clamp and dry.

Next Previous